Click image for close-up Click image for close-up

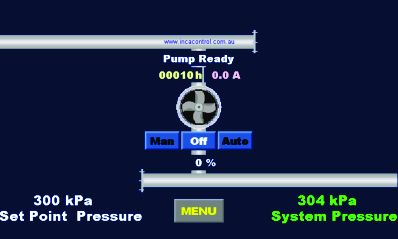

PV1 (Single V.S.D Touchscreen Pressure System Pump Controls)

PV1 (Single V.S.D Touchscreen Pressure System Pump Controls)

IMAGE 5-1:

The Single Variable Speed Drive Pressure System Pump Control is designed for ease of set up and operation. It provides power savings against a full speed system as a small reduction in pump speed provides a large reduction in power drawn. The V700 colour touch screen displays the system pressure and set point along with each pump Manual/Off/Auto selectors. Panels can be manufactured with tank level monitoring and bypass or makeup valve controls.

Customising the control system to your requirements is available including logos and passwords within the V700 screen.

The PV1 comes standard with:

Circuit Breakers for each pump and control circuit.

Main isolating switch.

Variable frequency inverters housed inside panel c/w required fan cooling.

Automatic pipe fill.

Motor current display.

Standard Ethernet port communication.

INCA model V700 HMIPLC c/w display of:

Pressure set point

System Pressure

Pump status c/w pump speed indication and total hour run for each pump.

Low discharge pressure indication.

Manual/Off/Auto button with manual speed increase and decrease buttons.

Data logging of all fault conditions up to 5000 logs.

Graphical trending of system pressure.

0-1000kpa pressure transducer - loose supplied.

Voltage free contacts for pump run/pump fail/system fault.

Supplid with 2mt Screened motor cable

All housed in a metal enclosure size to suit motor sizing

|

Click image for close-up Click image for close-up

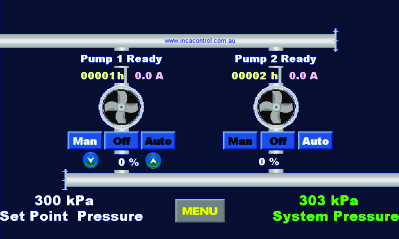

PV2 (Dual V.S.D Touchscreen Pressure System Pump Controls)

PV2 (Dual V.S.D Touchscreen Pressure System Pump Controls)

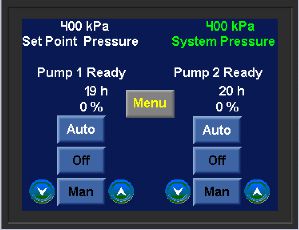

IMAGE 5-2:

The Dual Variable Speed Drive Pressure System Pump Controls is designed to maintain a constant system discharge pressure via feedback from the discharge pressure transducer.

The controller has been arranged for ease of set up and operation for the end user.

The panel provides power saving against full speed pump system as a small reduction in pump speed provides a large reduction in power drawn.

The PV HMI displays the system pressure along with all pump status, motor speeds and control switches. Panel can be manufactured with tank level shutdown and bypass or makeup valve controls.

The PV2 comes standard with:

Circuit Breakers for each pump and control circuit.

Automatic alternation after each pump operation.

Main isolating switch.

Variable frequency inverters housed inside panel c/w required fan cooling.

Automatic pipe fill.

Motor current display.

Standard Ethernet port communication.

INCA model V700 HMIPLC c/w display of:

Pressure set point

System Pressure

Pump status c/w pump speed indication and total hour run for each pump.

Low discharge pressure indication.

Manual/Off/Auto button with manual speed increase and decrease buttons.

Duty selector buttons for pump out of service operation.

Automatic pump test facility based on time since last pump run.

Modulating 1 or both pumps selectable.

Data logging of all fault conditions up to 5000 logs.

Graphical trending of system pressure.

0-1000kpa pressure transducer - loose supplied.

Voltage free contacts for pump run/pump fail/system fault.

Supplid with 2mt Screened motor cable

All housed in a metal enclosure size to suit motor sizing

|

Click image for close-up Click image for close-up

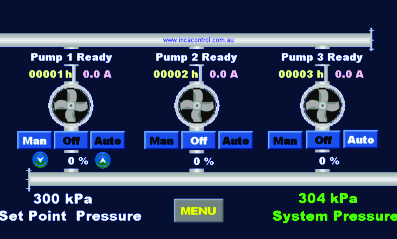

PV3 (Triplex V.S.D Touchscreen Pressure System Pump Controls)

PV3 (Triplex V.S.D Touchscreen Pressure System Pump Controls)

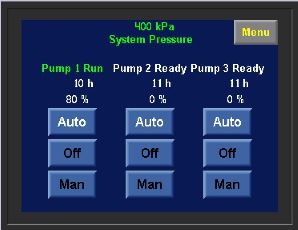

IMAGE 5-3:

The Triplex Variable Speed Drive Pressure System Pump Controls is designed to maintain a constant system discharge pressure via feedback from the discharge pressure transducer.

The controller has been arranged for ease of set up and operation for the end user.

The panel provides power saving against full speed pump system as a small reduction in pump speed provides a large reduction in power drawn.

The PV HMI displays the system pressure along with all pump status, motor speeds and control switches. Panel can be manufactured with tank level shutdown and bypass or makeup valve controls.

The PV3 comes standard with:

Circuit Breakers for each pump and control circuit.

Automatic alternation after each pump operation.

Main isolating switch.

Variable frequency inverters housed inside panel c/w required fan cooling.

Automatic pipe fill.

Motor current display.

Standard Ethernet port communication.

INCA model V700 HMIPLC c/w display of:

Pressure set point

System Pressure

Pump status c/w pump speed indication and total hour run for each pump.

Low discharge pressure indication.

Manual/Off/Auto button with manual speed increase and decrease buttons.

Duty selector buttons for pump out of service operation.

Automatic pump test facility based on time since last pump run.

Modulating 1 or both pumps selectable.

Data logging of all fault conditions up to 5000 logs.

Graphical trending of system pressure.

0-1000kpa pressure transducer - loose supplied.

Voltage free contacts for pump run/pump fail/system fault.

Supplid with 2mt Screened motor cable

All housed in a metal enclosure size to suit motor sizing

|

Click image for close-up Click image for close-up

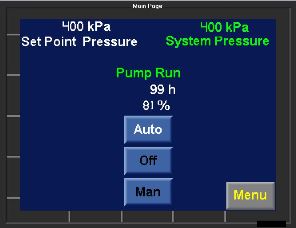

PVS1 (3.5" Touchscreen Single V.S.D Pressure System Pump Control Panel)

PVS1 (3.5" Touchscreen Single V.S.D Pressure System Pump Control Panel)

IMAGE 5-5:

The Single SAMBA V.S.D (Variable Speed Drive) Pressure System Pump Control panel is designed for ease of set up and operation for the

end user. It provides power saving against full speed system as a small reduction in pump speed provides a large reduction

in power drawn. The SAMBA HMI displays the system pressure along with all pump status, motor speed, and control switches.

The PVS1 comes standard with:

Circuit Breakers for Pump and Control Circuit

Main Isolating Switch

Variable Frequency Inverter housed inside panel c/w required Cooling Fan.

Inca Model PVS1 Controller c/w display of:

System Pressure

Pump Status c/w Pump Speed Indication and total hours run

Low Discharge Pressure Indication

Manual/ Off /Auto selector button with manual speed increase and decrease

High Pressure Pump shutdown with automatic reset

Low Pressure Pump shutdown with manual reset

PID loop controlled c/w automatic tuning of loop to system and pump response.

Data logging of all fault conditions up to 1000 logs

Low Level Suction Tank Shutdown (if connected)

Voltage Free Contact for system fault- Relay on terminal strip providing change over contacts for the building monitoring system for System Fault

0-1000 kpa Pressure Transducer - loose supplied.

Supplied with 2 Metres of Screened Motor Cable.

All equipment housed in a metal wall mounted enclosure size to suit motor sizing.

|

Click image for close-up Click image for close-up

PVS2 (3.5" Touchscreen Dual V.S.D Pressure System Pump Control Panel)

PVS2 (3.5" Touchscreen Dual V.S.D Pressure System Pump Control Panel)

IMAGE 5-6:

The Dual SAMBA V.S.D (Variable Speed Drive) Pressure System Pump Control panel is designed for ease of set up and operation for the

end user. It provides power saving against full speed system as a small reduction in pump speed provides a large reduction

in power drawn. The SAMBA HMI displays the system pressure along with all pump status, motor speed, and control switches.

The PVS2 comes standard with:

Circuit Breakers for Pump and Control Circuit

Main Isolating Switch

Variable Frequency Inverter housed inside panel c/w required Cooling Fan.

Inca Model PVS1 Controller c/w display of:

System Pressure

Pump Status c/w Pump Speed Indication and total hours run

Low Discharge Pressure Indication

Manual/ Off /Auto selector button with manual speed increase and decrease

High Pressure Pump shutdown with automatic reset

Low Pressure Pump shutdown with manual reset

PID loop controlled c/w automatic tuning of loop to system and pump response.

Data logging of all fault conditions up to 1000 logs

Low Level Suction Tank Shutdown (if connected)

Voltage Free Contact for system fault- Relay on terminal strip providing change over contacts for the building monitoring system for System Fault

0-1000 kpa Pressure Transducer - loose supplied.

Supplied with 2 Metres of Screened Motor Cable.

All equipment housed in a metal wall mounted enclosure size to suit motor sizing.

|

Click image for close-up Click image for close-up

PVS3 (3.5" Touchscreen Triplex V.S.D Pressure System Pump Control Panel)

PVS3 (3.5" Touchscreen Triplex V.S.D Pressure System Pump Control Panel)

IMAGE 5-7:

The Triplex SAMBA V.S.D (Variable Speed Drive) Pressure System Pump Control panel is designed for ease of set up and operation for the

end user. It provides power saving against full speed system as a small reduction in pump speed provides a large reduction

in power drawn. The SAMBA HMI displays the system pressure along with all pump status, motor speed, and control switches.

The PVS3 comes standard with:

Circuit Breakers for Pump and Control Circuit

Main Isolating Switch

Variable Frequency Inverter housed inside panel c/w required Cooling Fan.

Inca Model PVS1 Controller c/w display of:

System Pressure

Pump Status c/w Pump Speed Indication and total hours run

Low Discharge Pressure Indication

Manual/ Off /Auto selector button with manual speed increase and decrease

High Pressure Pump shutdown with automatic reset

Low Pressure Pump shutdown with manual reset

PID loop controlled c/w automatic tuning of loop to system and pump response.

Data logging of all fault conditions up to 1000 logs

Low Level Suction Tank Shutdown (if connected)

Voltage Free Contact for system fault- Relay on terminal strip providing change over contacts for the building monitoring system for System Fault

0-1000 kpa Pressure Transducer - loose supplied.

Supplied with 2 Metres of Screened Motor Cable.

All equipment housed in a metal wall mounted enclosure size to suit motor sizing.

|

|